Unique expertise

The Flavy X-Wine filter has a reputation on the market for giving the best flow rates with the most difficult wines. This result is the fruit of 30 years’ experience in wine filtration. Controlling clogging, combined with a gentle (very low pressure), flexible process and a high-performance filtration membrane, ensures stable, regular flow rates throughout the filtration process.

A wide range of applications

The Flavy X-Wine filter is extremely versatile, capable of treating raw wines with high turbidity, red wines from thermovinification, wines from cold storage (-4°C), fined wines, sparkling wines and wines ready for bottling. With this filter you can also block fermentation and filter wines containing PVPP.

Low environmental impact

The Flavy X-Wine filter stands out for having the lowest consumption of water and cleaning products on the market.

The washing water separation option contributes even further to reducing the environmental impact by allowing the last filter rinsing water to be reused for other purposes in the cellar (vat room cleaning, floor cleaning, etc.).

Finally, the Flavy X-Wine filter, is renowned for preserving the quality of filtered wines and its rock-solid reliability.

| Technical data | X-Wine 2 | X-Wine 3 | X-Wine 4 | X-Wine 6 | X-Wine 8 | X-Wine 10 |

|---|---|---|---|---|---|---|

| Length (mm) | 2390 | 2390 | 2940 | 2940 | 3310 | 3,310 |

| Width (mm) | 1740 | 1740 | 2230 | 2230 | 2380 | 2380 |

| Floor area (m2) | 7 | 7 | 10 | 10 | 11 | 11 |

| Height (mm) | 1980 | 1980 | 2200 | 2200 | 2190 | 2190 |

| Unladen weight (kg) | 710 | 740 | 1310 | 1380 | 1650 | 1720 |

| Supply voltage (V/Hz) | 400 Volts three-phase + Earth (50 Hz) | 400 Volts three-phase + Earth (50 Hz) | 400 Volts three-phase + Earth (50 Hz) | 400 Volts three-phase + Earth (50 Hz) | 400 Volts three-phase + Earth (50 Hz) | 400 Volts three-phase + Earth (50 Hz) |

| Total power (kW) | 10 | 10 | 18 | 14 | 27 | 27 |

– On-line measurement of turbidity in filtered wine

– Automatic verification that there are no detergent residues after regeneration. Control and safety tool required for IFS-BRC type audits.

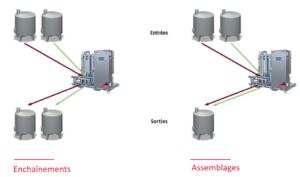

– Enables you to create filtration sequences or assemblies

– Protein stabilization of white and rosé wines

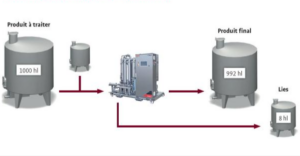

– Simplifying the wine processing chain

– Fewer cleaning operations for pumps, pipes and winery

– Wine treatment without the use of additives

– Wines available for bottling more quickly

– No more tank bottom management, which can represent 3 to 5% of the volume treated

– Injection of up to 3 oenological products (e.g.: MCR, metatartaric acid, UF bentonite) and 3 at the filter outlet (e.g.: CMC, SO2, gum arabic)

This option makes it possible to control a solenoid valve and a diffuser located after the filter outlet valve.

– In the case of water with a fouling index > 3, we recommend installing 3 stages of water filtration (5 µ – 1µ – 0.5 µ) for maximum efficiency of rinsing and washing operations.

– Makes it possible to separate washing water from the last filter rinsing water

– Recover this clear water for other uses

– Helps reduce water consumption in the cellar

– For wine filtration in closed tanks, up to 7 bars.

– Sterilizable sampling tap suitable for microbiological analysis

– Adjusts back pressure to ensure good quality retrofiltration. To be used, for example, when the receiving tank is located at the bottom of the filter

– Flavy X-Wine 4-6 filters are supplied on wheels. They can be placed on feet when in a fixed position.

– For cold wine filtration. Protects the filter from scale crystals.

– When hot water production is far from the filter.

From performance to peace of mind, with Bucher Vaslin services.

Find a dealer

Selected for their professionalism, Bucher Vaslin dealers advise you and guarantee quality local service.

Join us

Interested in a career with Bucher Vaslin? Take a look at our job offers or apply directly on our website.