More complex wines with greater aroma and colour stability

The absence of oxidation protects the natural antioxidants extracted from the grapes, which contribute to the longevity of the aromas and colour.

These compounds are protected if oxygen levels are below 2%. Above this threshold, even if the musts appear protected (greener colour), the antioxidants are destroyed and the aromas are no longer protected.

A rapid return on investment

The gas is recycled in a flexible reservoir, which means it can be used for 10 pressings in a row, reducing gas consumption.

The process is fully automated, requiring no additional manpower.

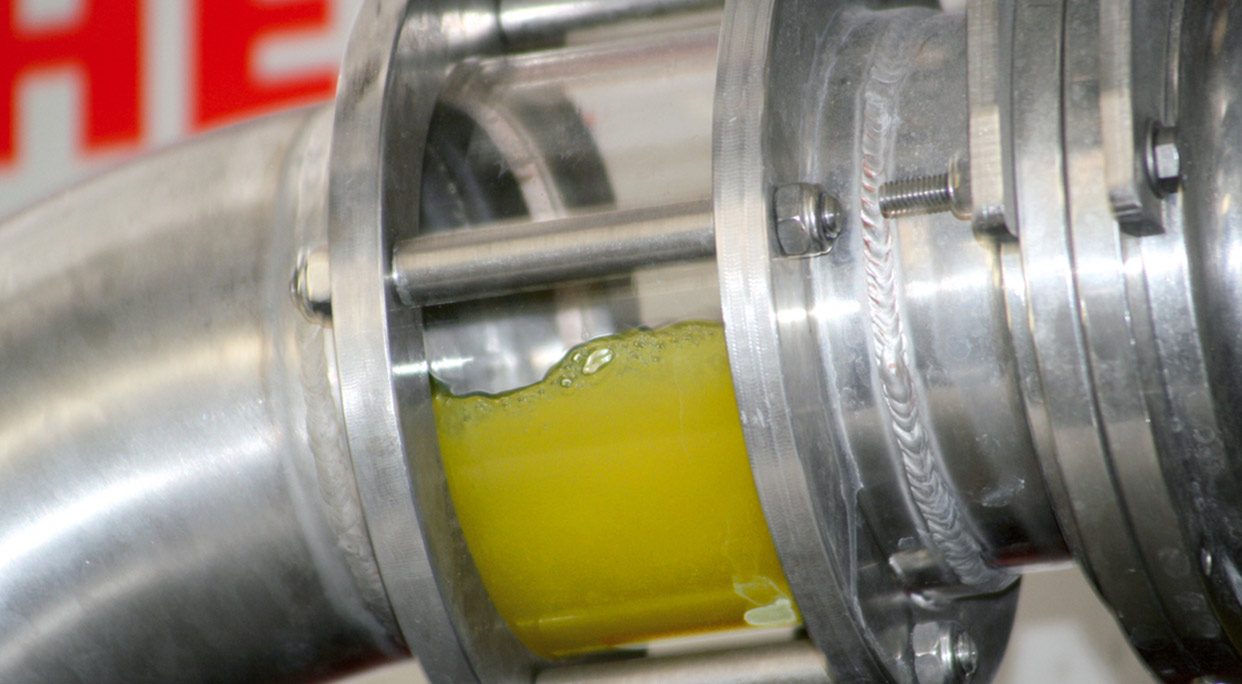

Pressing takes place under a neutral gas that is recycled in a tank close to the press. The volume of the flexible tank is equivalent to the capacity of the press.

During phases of breaking up the press cake, the neutral gas from the tank is sucked out by moving the membrane in the press (evacuation). During pressurisation, the membrane in the press pushes the neutral gas towards the flexible tank. The harvest and the juice are not oxidised during phases of breaking up the press cake and pressurisation.

From performance to peace of mind, with Bucher Vaslin services.

Find a dealer

Selected for their professionalism, Bucher Vaslin dealers advise you and guarantee quality local service.

Join us

Interested in a career with Bucher Vaslin? Take a look at our job offers or apply directly on our website.